A company whose reputation relies on better than perfect hygiene

SaniSped is a company specializing in transporting blood, organs, vaccines, and other medical apparatus, i.e. sterile products.

The products transported by SaniSped absolutely must be sterile at the time of administration. The sterility of a product in its primary packaging is established by the supplier or manufacturer. Between production and administration, the product is handled and exposed to a variety of environments, more or less controlled: refrigerated warehouses, transport vehicles, loading docks, etc.

To protect a product from external contamination throughout the supply chain, it is packed in a secondary packaging, which is placed in a hermetic isothermal container, which then in-turn is placed in a transport case.

The transport case is removed at the destination when first unloaded, then the container at the destination storage point, and finally the secondary and primary packaging are removed at the time of use.

To maintain the quality of their services, SaniSped makes sure containers are regularly cleaned, disinfected, and checked. For the controls, regulatory surface samples are taken:

– At least 2 tests were conducted per year

– Samples were taken from each contact box, on 10 transport boxes for sensitive products

– Testing was subcontracted to an external laboratory

– Tolerance: up to 25 cfu / 25 cm2

This testing regime was insufficient, however, to verify that the hygiene procedures were effective at all times.

Looking for a competitive edge in sterile transport

With a concern about the quality of services, SaniSped’s Innovation Manager, Simon, contacted BioMire to inquire about conducting a study. For Simon, the hygiene regimens implemented by SaniSped were a critical aspect of the company’s competitive edge, allowing them to claim better quality services compared to their competitors. Simon was looking for an investigation that would support the quality claims of SaniSped services with measurable data.

Accurately measuring hygiene levels throughout the supply chain, without extra staff

For the study to make sense, SaniSped needed results that were both useful to verify the quality of their services, but also to allow for improved cleaning and monitoring programs in the future.

To meet these objectives, this required:

- Testing devices that were easy to use on- and off-site by non-specialized personnel, quickly while maintaining result quality.

- Applicability throughout the supply chain, despite variables in the nature and shape of the surfaces to be controlled, the sampling conditions without multiplying protocols and equipment.

- Comparability, producing quantitative data correlated to a reference technique, so that correspondences could be established.

- Analytical criteria including accuracy (comparison with the reference method) dynamic range (adapted to “very clean” and “less clean”) robustness (adapted to the diversity of situations).

Specificity, linearity, repeatability, reproducibility, detection limit are lesser technical selection criteria.

Improving quality to reassure the client and the company itself

Specifically, the investigation needed to show whether the cleaning and sanitization protocols in place were effective, and the study extended from the moment of reception to delivery of materials.

A study method using high quality testing devices and connected smart apps

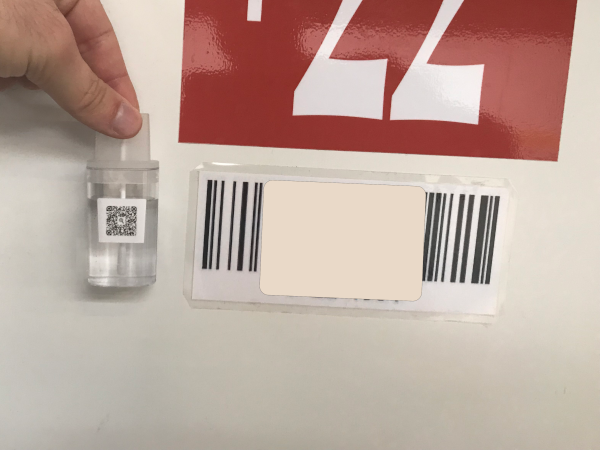

SaniSped decided to implement a nomad microbial risk management plan in order to make use of fully integrated nomad Dip Testers as well as the nomad Smart Microbiology Apps.

The high portability of nomad testing devices was well-adapted to testing throughout the supply chain, while also being configured with QR Codes for IoT integration.

The nomad Mobile App made paperless recording of all relevant data at the sampling point, including user comments, GPS location of the test, and adding pictures to the sample records. In this case, users added photos of the vehicle plate numbers or the wall or case ID bar codes.

Random auditing of containers, facilities and vehicles

During the study:

- Samples were taken inside the containers to check the consistency of the results with those obtained by the reference technique. (Please note that the techniques were not used simultaneously on the same container.)

- Samples were taken from the walls of the preparation and storage rooms.

- Random sampling was performed on transport crates.

- Samples were taken from a refrigerated van: the door handle, the floor, the grid of the refrigeration unit.

Reliable testing reveals that even regular cleaning leaves high risk points

Results showed both effective hygiene and high-risk points.

- The result obtained on the inside of the container was consistent with those obtained historically by the reference technique.

- All the points sampled gave results indicative of “clean” surfaces,

with the exception of those taken from the refrigerated van. - In the case of the refrigerated van, the refrigeration unit appeared to be significantly more contaminated than the other sampling points.

The nomad solution was adapted to the operational and analytical constraints of this study, however at its conclusion the samples were insufficient to establish:

- reference values from which an alert threshold could be established

- risks throughout the supply chain

- Further investigations would be necessary to deal with these problems.

Ventilation grids can be the cause of nasty surprises

The highest counts were obtained on the samples from the ventilation grids. Ventilation grids are known to be a source of contamination are listed as points to verify in the WHO guidelines for sampling of coronavirus in healthcare settings and as general recommendations to the food industry.among other guidelines.

Airborne micro-organisms tend to deposit on the grid where they can find conditions to grow, in particular if the presence of condensation. Then they are susceptible of being spread in the air again, creating a contamination risk.

To make things worse, the grids are difficult to clean and decontaminate without dismantling them.

Often overlooked, ventilation grids are a potential source of contamination.

Keeping our eyes open for the weak point in the chain

“Life moves pretty fast. If you don’t stop and look around once in a while, you could miss it.” (Ferris Bueller) applies well in the context of environmental monitoring.

Microbe-wise – A quick look at Penicillium

Penicillium’s a fungi of major importance in the natural environment, in food spoilage, and in food and drug production. In latin, penicillatis means « with a brush (of fine hair)».

Species of Penicillium are ubiquitous, preferring cool and moderate climates, grow well around 25°C. Some species grow into a blue fuzzy texture.

Penicillium species are present in the air and dust of indoor environments, such as homes and public buildings. The fungus can be readily transported from the outdoors, and grow indoors using building material or accumulated soil to obtain nutrients for growth. Penicillium growth can still occur indoors even if the relative humidity is low, as long as there is sufficient moisture available on a given surface.

Disclaimers

This Use Case is based on a true story! (Though we edited it for readability and, of course, for confidentiality.) We like to share stories about real situations because we think they help translate raw facts into helpful insight and understanding. We’re providing this use case as an illustration, but it does not imply that the same conclusions can be made in similar cases. We will be happy to discuss it, however, as well as how the particulars of this case might be transferable to your situation—so don’t hesitate to contact us! Also, please be aware that we do sometimes use automatic translations, which might slightly distort the information.