The solution for fighting microbial contamination in breweries

If you know a brewer or are one yourself, you know that cleaning is a major part of brewing. Whether you are a one-person craft brewery or a multi-site producer, hygiene management is an essential part of your business.

The application of a good Cleaning In Place (CIP) system in keeping with the recommendations of equipment and hygiene product manufacturers is good brewing practice, but the concentration of production steps in the same permanently humid environment is conducive to microbial recontamination. Furthermore, low-level contamination during packaging can impact the quality of your beers and your reputation.

Managing all the risks can be daunting, but many brewers are so close to the workings of their brewery that their observations and insights naturally lead them to the trouble spots. We offer solutions for all types of production to help you turn your insights into knowledge.

SERVICE PACKS, DEDICATED SOLUTIONS FOR CRAFT BREWERIES

We offer turnkey services adapted to specific situations

Hygiene assessment pack for craft breweries

YOUR SITUATION

A craft brewery producing less than 1,000 hl/year. Your hygiene controls are mainly visual, supplemented by occasional microbial analyses

WHAT IS MISSING

An assessment of the quality of your cleaning at critical points and a comparison with peers, which means a sampling plan, test devices and assistance with analysing results

THE FEATURES YOU WANT

- An personalised list of critical points to check

- A way to carry out the checks yourself without a laboratory

- Assistance in interpreting the results and drawing conclusions

INCLUDED

- Customised services

- Subscription to online services

- Necessary test devices

Contamination Diagnostic Pack

YOUR SITUATION

You want to locate the source of recurrent or sporadic contaminations, correct your practices and verify that the correction is stable, which means a sampling plan, test devices and assistance with analysing results

WHAT IS MISSING

A troubleshooting test campaign, which you can redeploy yourself throughout the life of the brewery according to its needs

THE FEATURES YOU WANT

- An organised selection of sampling points to be monitored, based on the manifestation of your contamination concern and specific to your brewery, to:

- Locate the contamination origin and identify loopholes in hygiene practices and

- Check the corrective actions have durably addressed the concern,

- A means of carrying out controls yourself without an external laboratory

- Assistance in interpreting the results and drawing conclusions

INCLUDED

- Customised services

- Subscription to online services

- Necessary test devices

Brewery hygiene monitoring Pack

YOUR SITUATION

Your hygiene practices are thorough, and the cleanliness of equipment is visually checked, supplemented by analyses other than microbiological

WHAT IS MISSING

A simple and tailored systematic monitoring plan, which you can develop yourself throughout the life of the brewery according to its needs

THE FEATURES YOU WANT

- A list of critical points to be monitored, based on a risk assessment specific to your brewery, to control:

- hygiene practices throughout the process and

- contamination risks from the production environment

- A means of carrying out checks yourself without an external laboratory

- Assistance in interpreting the results and drawing conclusions

INCLUDED

- Customised services

- Subscription to online services

- Necessary test devices

See more Packs for Breweries

TURNKEY TOOLS TO CONTROL CONTAMINATION RISKS ON YOUR OWN

Do you want to check that your equipment and lines are clean and sanitary before introducing the must, or check that your bottling equipment is clean?

nomad Smart Microbial Solutions can help you ensure consistent product quality, peace of mind and protect your reputation.

nomad On-Site Microbial Test Kits fit in your pocket, allowing you to test directly at the brewery, where it matters most, in minutes and with minimal effort.

With nomad Smart Microbiology Apps, monitoring and managing results is as easy as scanning a QRCode. Automatic colony counting, customised alert levels and other features provide greater visibility.

Microbiological monitoring experts are available to help you set up and implement the right sampling plan for your equipment and recipes.

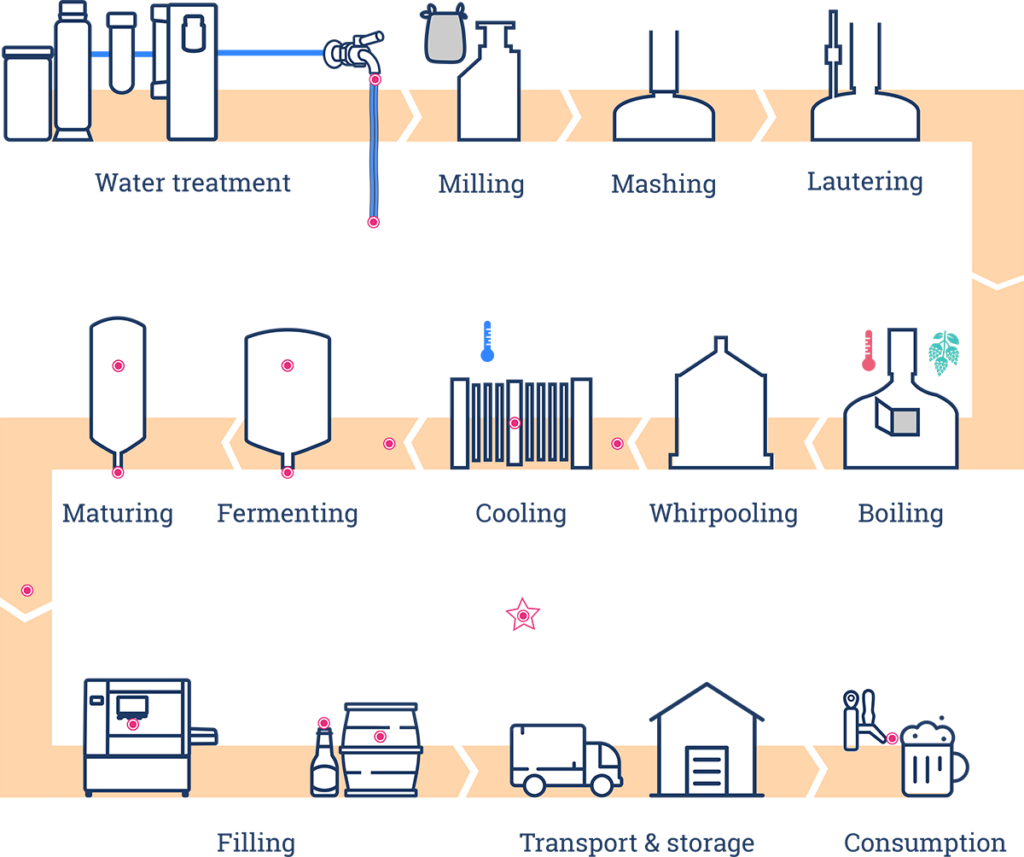

MICROBIAL CONTAMINATION RISKS IN BREWERIES

Compared to other industries, the brewing industry is subject to more diverse and higher risks of contamination than others. Preventive measures exist but are sometimes difficult to apply effectively at all critical points. The implementation of a monitoring plan helps to ensure that they are effective as well as to identify the critical points to be cleaned regularly.

Water

- Microbial risks: Water stagnation – Pseudomonas, Enterobacterium, Cladosporidium…

- Consequences: Formation of biofilms

- Prevention: Design and maintenance of water treatment system, short storage at low or high temperature

Malts

- Microbial risks: storage conditions, rodents – Fusarium, Lactobacillus…

- Consequences: Mycotoxins inhibit yeast, flocculation, over-foaming…

- Prevention: Store dry and at low temperature, protection against pests

Equipment

- Microbial risks: Cleaning water, cross-contamination from other equipment and the environment – Water flora, lactic acid bacteria, enterobaceriaceae, Gluconobacter

- Consequences: Production of acetaldehydes, diacetyl…

- Prevention: Physical separation/distancing between equipment, maintenance, NEP/CIP,

Heat exchanger

- Microbial risks: Incomplete cleaning – Enterobacteria, Lactobacilli, Pediococci, Yeast

- Consequences: Unpleasant flavours, inhibition of Saccharomyces

- Prevention: NEP/CIP – rapid fermentation after cooling

Fermentation

- Microbial risks: Incomplete cleaning-disinfection, periods of non-use, introduction of ingredients – Hop-resistant Lactobacilli, Paediococcus, acetic acid bacteria, Zymomonas (if sugar added).

- Consequences: Acidification, cloudiness, unpleasant aroma.

- Prevention: NEP/CIP, limited environmental exposure, drying between uses

Packaging

- Microbial risks: Cleanliness of equipment and containers (drums, bottles) – Flora described above, formation of biofilms

- Consequences: Reduction of microbial stability

- Prevention: pasteurisation (infrequent)

Our Solutions

We offer a range of options, from simple stand-alone testers to turnkey service packages.

On-site Microbiological Tests

The nomad kits allow you to count bacteria, yeast and moulds in liquids and on surfaces as accurately as with laboratory techniques, while remaining easy to store and use. The red testers, recommended for brewery applications, are available in two formats, standard and with a QRCode to work with the nomad Smart Microbiology Apps.

Cloud-based microbial monitoring solutions

nomad Smart Microbiology subscriptions give you access to fully integrated mobile and web-based applications that simplify on-the-spot sampling, automatically count colonies, and allow efficient use of your data history. Available plans start with a free option and can be upgraded for access to more results, users and sites as well as additional functionality to grow with your needs.

Quick-start nomad microbiology services

nomad Quick-Start Services include one-on-one assistance in setting up and developing your monitoring plan with risk analysis, sample planning and results analysis. These service packages are combined with test kits and subscriptions that match your needs and are offered at a reduced price.

FIND OUT HOW BIOMIRE CAN HELP YOU AVOID CONTAMINATIONS

Partnering with independent brewers

We are suppliers of NEGO BRASS’, the central purchasing office of the SNBI, a French syndicat representing 1800 independent breweries in France. Because our solutions are scalable, we are here to help you protect the quality of your beer, whether you are a microbrewery or a larger operation.

At Zoobrew, we brew really different and unique beers. We have grown fast since the beginning 6 years ago.I started using nomad to do our microbial monitoring. It’s super easy to use and it’s reassuring to have quantitive results to say if all is well.

J.B. – passionate brewer at Zoobrew – France

Use cases

The road to solving a microbial monitoring challenge can be paved with questions about what means to use to reach an end. These Use Cases are based on real experiences, to illustrate how other companies have approached overcoming their specific challenges, often using methods and thought processes that are common to many manufacturers.